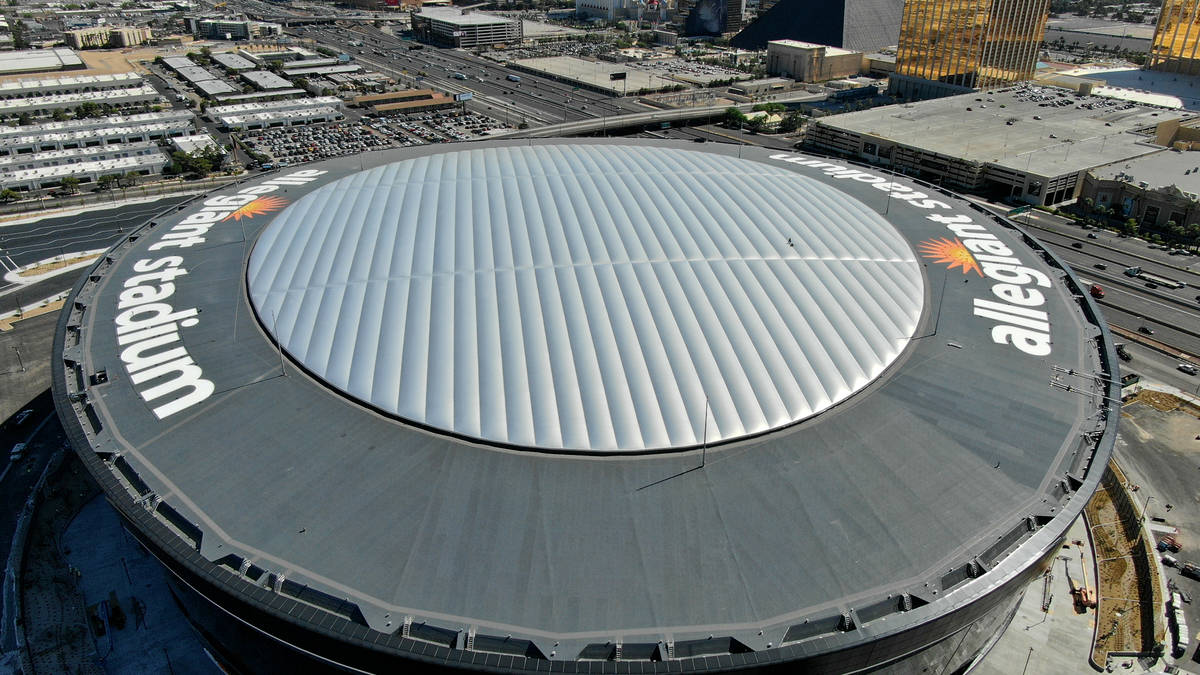

Allegiant Stadium’s intricate roof system a pain in the neck

Allegiant Stadium’s steel cable net roofing system is one piece of the construction puzzle that seemingly could have knocked the long-touted July 31 substantial completion date off track.

Ahead of the roofing system’s installation, Don Webb, chief operating officer of the Raiders’ construction subsidiary, said the complexity of the process left little room for error.

Originally slated to be in place in early November, the roofing system is comprised of 100 steel cables in a crosshatch pattern — stretching as long as 800 feet and weighing up to 24 tons — that support a translucent roof of ETFE (fluorine-based plastic) roofing panels.

The cables first were laid out on the stadium floor and then slowly lifted toward the roof, when the initial lift of the cables hit a snag.

When the lifting process started in August, the stress of stretching the cables from the various nodes on the roof caused some bolts in the system to break. Several teams of engineers were brought in to address and solve the problem.

Despite the issue, crews were able to raise the cables high enough during the initial lift to allow for work below to begin, taking the roof system off the critical path in the stadium’s project schedule.

After addressing the issue, the lift was back on track, finishing in mid-February, months after initial plans.

The design-build plan of the stadium enabled workers to take some tasks that were scheduled to be completed later in the spring and carry out that work ahead of time to make up for the months the roofing system was delayed.

Crews worked furiously to get the roofing panels in place following the “big lift” of the cable net roof system, fully enclosing the stadium by mid-April.

Contact Mick Akers at makers@reviewjournal.com or 702-387-2920. Follow @mickakers on Twitter.