Bigelow Aerospace wants Mars trip to go through North Las Vegas

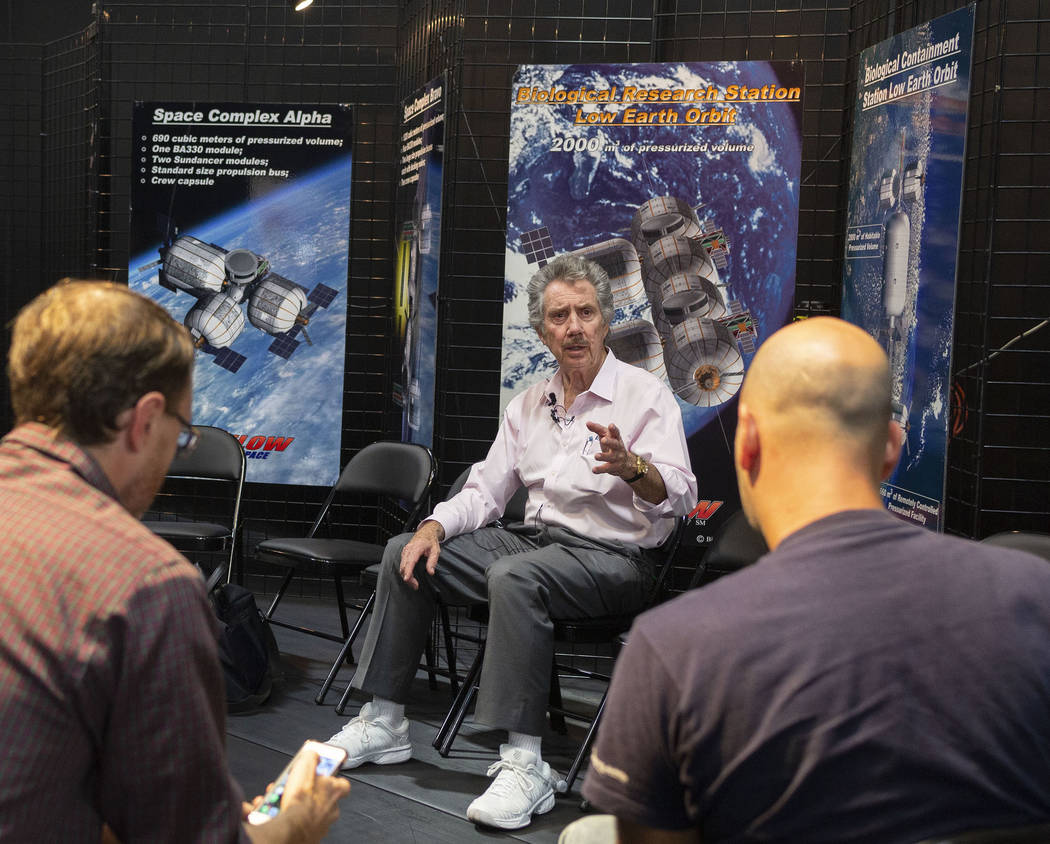

Robert Bigelow is working to make sure the pathway to Mars runs through North Las Vegas.

Bigelow and his Bigelow Aerospace manufacturing facility played host to eight NASA astronauts and 60 engineers this week — some spending several days getting to know the company’s B330 autonomous, expandable space station.

The versatile inflatable module can be used as a transport vehicle on a lengthy space voyage, and can be attached by airlock to existing space stations or serve as a base of operations on a planet surface or the moon.

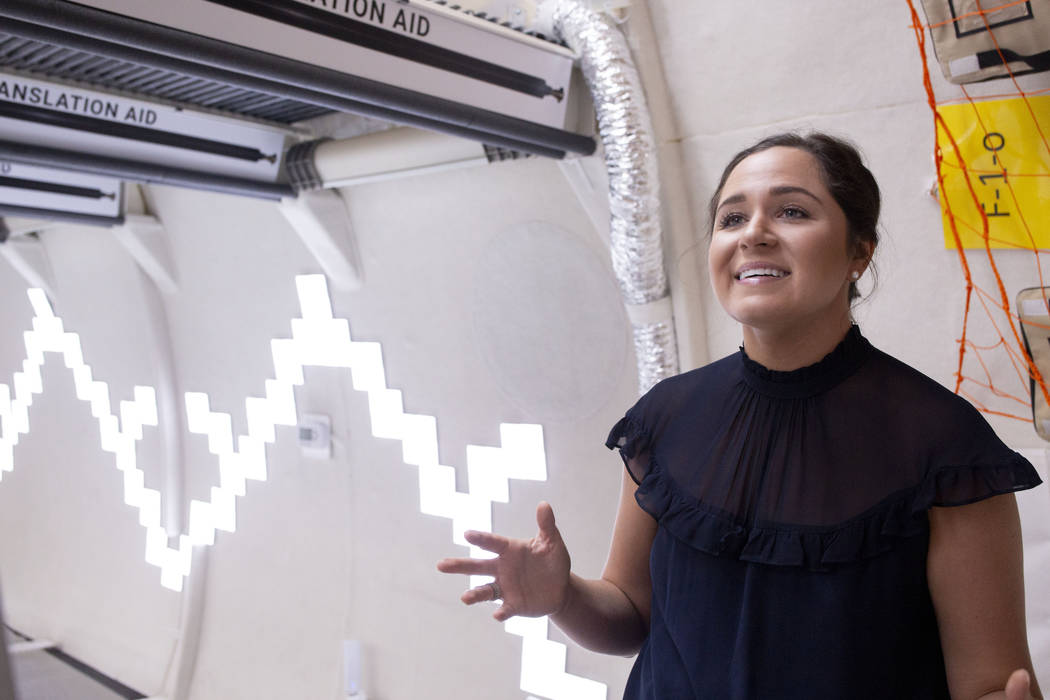

Bigelow and his staff hosted reporters Thursday to show off a mock-up of the B330 and provide updates on other Bigelow projects, including the Bigelow Expandable Activity Module (BEAM), which recently observed its third anniversary attached to the International Space Station.

The company also showed off Olympus, Bigelow’s massive space station prototype that’s only in concept stages today, but for which there is a life-size model within the production facility.

“We’re in competition with other companies that are going through this testing process where NASA has been sending in their astronauts to critique the good, the bad and the ugly of companies’ hardware, their enclosures, their architecture and whatever and that’s the process we’re going through,” Bigelow said in a briefing.

Bigelow said the company has made modifications based on the astronauts’ comments, changing a handhold grip or slide-out seating here or there.

No stairs or floors

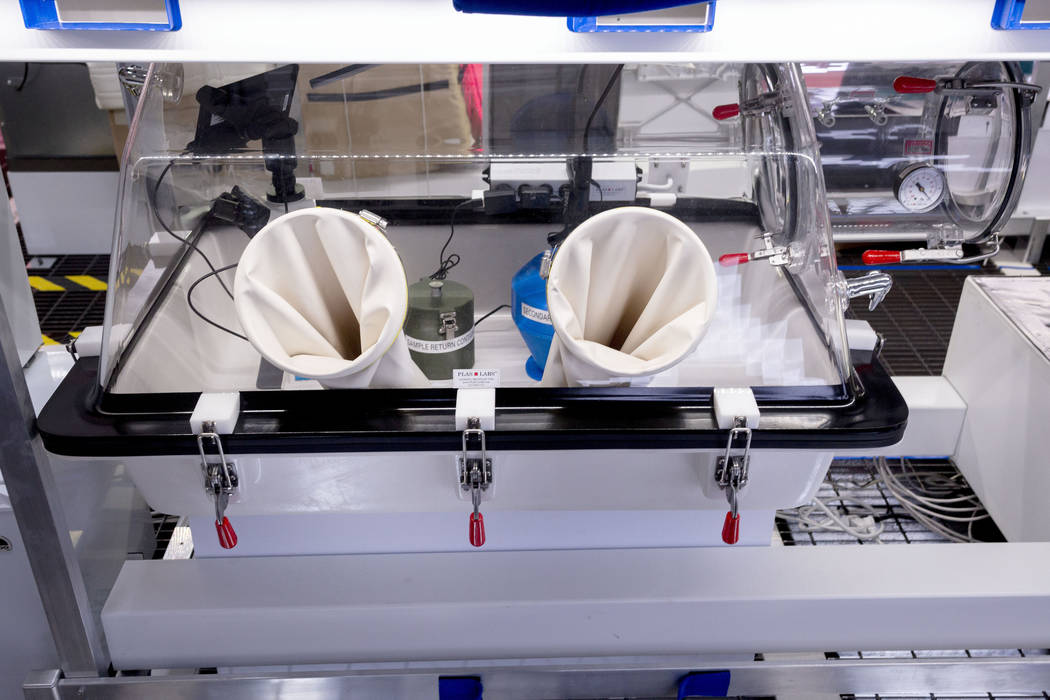

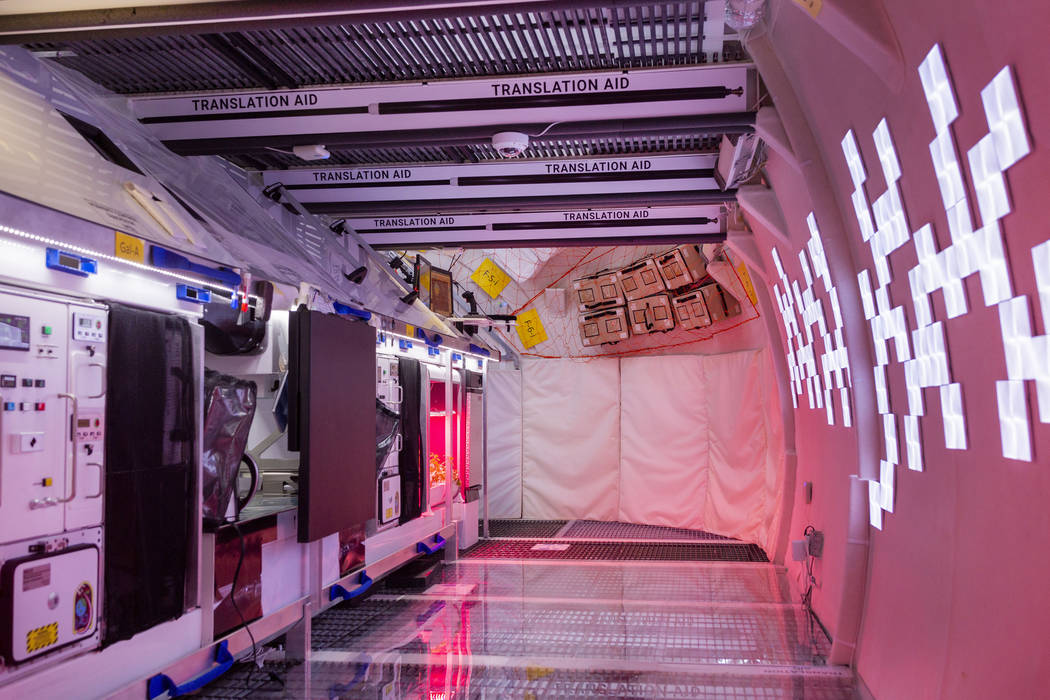

It’s somewhat difficult to envision the mobility possible in the B330 because in zero gravity, there’s no need for stairs or floors. In the mock-up, there are three levels of working space separated by metal grating, and signs abound, showing “translation aids” for movement within the space and “does not exist” to remind workers that in zero gravity, there’s no need for a particular feature.

Bigelow said the B330 would be able to sustain four people indefinitely or five or more for several months. Big, curved video screens match the concave surface of the fuselage. Engineers have found that it’s better to have screens and cameras instead of windows because cameras can be pointed in different directions or can capture a view of key systems on the exterior of the craft.

Each of the astronauts have their own private area with sleeping snug sacks attached to the walls. There’s a 3D printing station to manufacture objects as well as a communications station, two food-preparation areas and a zone to grow food.

“If you’re growing food, every one of these (growing units) can be rotating out and can become a hydroponic farm,” Bigelow explained. “They say that about 25 percent of your diet can be supplemented by what you grow on board. That’s significant. That’s a lot of supplies if 25 percent of what you’re going to ingest doesn’t have to be brought up.”

The station also is equipped with two toilets — a luxury for a space station, but an essential redundancy for a deep-space voyage.

Lots of storage space

Lining the walls and the ceiling are cargo nets filled with supplies. The living space is massive compared with other space-travel vehicles. The “330” in B330 refers to the 330 cubic meters of space inside.

Bigelow’s concept Olympus vehicle would have 2,250 cubic meters; the International Space Station has 932 cubic meters, with the American portion of the station just 428.

The American space on the ISS has been supplemented with the BEAM unit with an additional 16 cubic meters of space. Bigelow said the BEAM has performed better than expected since arriving at the ISS in April 2016 and expanded and pressurized a month and a half later. The unit has been recertified to stay with the ISS through 2028. It weighs 3,000 pounds and stows 3,400 pounds of gear.

Bigelow’s expandable units containing all the features designed for living in space are packaged into a cylinder and delivered in a payload fairing — the tube that sits atop the rocket that protects what’s launched into space. Company engineers had to make adjustments when the BEAM was launched because it was crammed into the SpaceX Dragon cargo vehicle in a “soup can,” Bigelow said.

Highly competitive market

The highly competitive development of station living spaces and Mars transport vehicles has always been ahead of the development of launch vehicles, but Bigelow is hopeful that more details from NASA will emerge next year to determine whether the North Las Vegas company will have a role in Mars missions.

Details are expected in 2020 on NASA’s Gateway program, a lunar outpost from which Mars missions would begin, and Bigelow seeks to be a player in the logistics of the voyage.

Bigelow would not disclose the cost of developing the station programs, citing it as proprietary information.

Contact Richard N. Velotta at rvelotta@reviewjournal.com or 702-477-3893. Follow @RickVelotta on Twitter.

'Big Brother' and 'Survivor' in space

One way Bigelow Aerospace founder Robert Bigelow figures to generate revenue for space exploration as well as build enthusiasm for space travel is through entertainment.

Bigelow envisions an opportunity for competitions among people interested in being launched into space through reality television competitions. He suggests that companies would be willing to pay big bucks for sponsorships on shows such as "Survivor," featuring competitors vying to earn seats on shuttle launches.

A weekly series could be developed showing competitors going through training and either moving on or getting washed out.

He also sees opportunity in something similar to "Big Brother," in which competitors would have to live together on a space station and try not to get on each other's nerves.

"I think it would be great entertainment that could draw a huge audience while calling attention to space travel," he said.