Third-generation machinist keeps wheels turning for Tonopah’s mining-centric economy

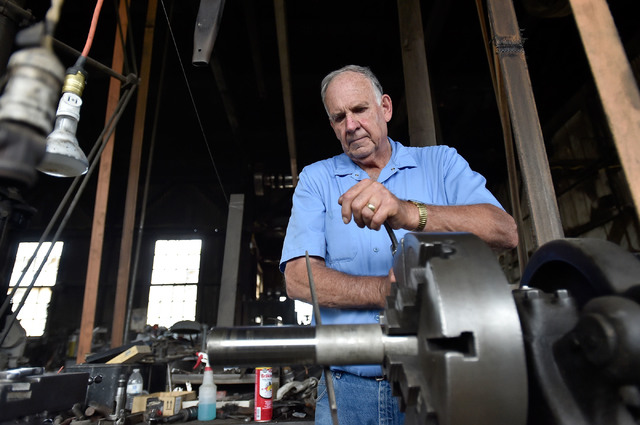

TONOPAH — John Campbell stands inside his machine shop here, a solitary figure flipping a switch into another time when the mines burst with gold, silver and opportunity.

Suddenly, amid the dust and scattered parts, a 19th century lineshaft groans to life overhead — a system of spinning wheels and pulleys that runs the grease-blackened contraptions that for decades have created and maintained mining’s often-complex heavy machinery.

At 66, the towering 6-foot-4 Campbell feels at home here, the third generation of his family to stand at the controls of these same humming behemoths in this very building. Before him came his father and grandfather — two visionaries who built Campbell & Kelly Foundry and Machine Works, a company that helped pour the iron and steel that shaped the American West.

Although the gold runs have tapered, Campbell uses these same century-old lathes, drills and grinders that his grandfather once sweated over to promote a 21st century endeavor: preparing parts used to mine the lithium that fuels Tesla’s new line of cars.

The unlikely practice of using yesterday’s tools to help build tomorrow’s economy comes straight from the Campbell clan’s personal playbook: “If it ain’t broke, don’t fix it.”

And if these machines do fail, there are no fast-and-easy factory replacement parts; Campbell must often forge new ones to continue his work as a heavy-metal engineer. It’s not as much out of any spirit of preservation as sheer necessity: These throwbacks are still hard at work.

“You’re just hoping to get the job done with these old machines before they quit,” he said. “And the next one and the next one.”

Many here say Campbell has become such an important cog in the workings of Tonopah, they’d be at a loss to carry on without him. For decades, as Bobby Jean Roberts and her late husband, Bill, ran the local newspaper, they frequently called on Campbell to fix aging press machines that had long before gone out of production.

“John helped keep the newspaper running for years,” she said. “He can fix anything.”

FORGED OUT OF NECESSITY

With the Campbells, that’s the way it’s been for 110 years. The family’s stubborn longevity mirrors the story of this historic outpost halfway between Las Vegas and Reno along U.S. Highway 95, a former boomtown that refuses to crumble back into the high-desert dust.

Over the years, the Campbell business suffered two debilitating fires, the first burning the enterprise to the ground in 1915. In the second, in 2012, John Campbell put out the blaze mostly by himself, before volunteer firefighters could even get there.

John’s grandfather, Horace P. Campbell, also died on these grounds. In 1944, he was nailing tin onto a shop roof during a windstorm when he was blown onto a live 480-volt wire.

His son, Horace Joseph Campbell, took the reins from there, and continued building the business he eventually turned over to his own son.

When Campbell was a boy, he learned from his gentle father. “It’s the love you develop between yourself and your parents – and the result is the work ethic they instill in you,” he said. “With men like my father, you go through life watching over their shoulder over the years. I did that a lot.”

Grandfather Campbell was a Scottish immigrant who in 1905 saw opportunity in the Nevada minefields: When machines broke down, a new part often had to be cast at far-off shops in Reno and even San Francisco.

He soon went into business with partner Reuben “Rube” Kelly to fill the gap, moving on to fashion mine cars, pumps and well drillers.

Winters were hard in the shop. Before the era of anti-freeze, machines were cooled with water that froze when the temperatures dipped into the 30s. But the men liked the challenge of taking a customer’s unformed idea and shaping it into a working product.

SHAPING A LEGACY

A few years ago, Nye County honored John Campbell’s life with a biography that consists of several interviews with the craftsman. The idea came from former county commissioner Joni Eastley, who calls Campbell “a quiet unassuming man with a heart as big as any piece of machinery he’s built.”

Eastley said much of rural Nevada was built by hardworking craftsmen like the Campbells.

“Many were self-taught engineers like John’s grandfather,” she said. “Was he formally trained? No, he didn’t go to school a day in his life. But that organic know-how was instilled in his son and his son’s son.”

Early on, Campbell decided to follow in his father’s footsteps, which meant staying in Tonopah. “Back then, I thought the earth was flat,” he said with a laugh. “Like I’d fall off if I wandered too far from home.”

Back then, he and his father were inseparable. Each morning, the kid would accompany the old man over to the Tonopah Club, where the elder Campbell and Emerson Titlow would sit around over coffee, trading town gossip and complaining about things.

In the afternoon, they’d come back and do it all over again.

One recent morning, dressed in jeans, a sky-blue shirt and dirty boots, Campbell wanders the 10-acre tract outside his machine shop; land littered with dozens of vintage Chevrolet wrecks from the 1950s and ’60s. Nearby, the unofficial guard dog, Roy the Rooster, squawks from his pen.

If television junkman Fred Sanford moved to Tonopah, this is where he’d do business, in a field of rusting pickups, sedans left with their doors wide open, a lost tumbleweed trapped beneath one steering wheel. There are disembodied car doors and left-behind engine parts.

Many of these castoffs have been parked here since John was a boy. For him, none of this stuff is considered junk, not at all; they’re all the framework of jobs to be done, the unmolded clay that goes into a new work of art.

But the job of taking precious metals from the ground has never been a steady provider. When the mines closed, Campbell needed new work. For years, he built fire trucks that he sold to departments across the West.

A few years back, he was running errands when he got a call that his shop was on fire.

A longtime volunteer fire chief, he raced over to the station, borrowed a truck and raced home.

“When I got there, the fire was roaring pretty good.”

His instincts kicked in.

“When you’ve been doing something for 100 years, you just get on with it.”

Later, he was flooded with calls and letters from friends and machine shop customers, wondering if he was safe and asking if he needed credit to stay on his feet. For Campbell, such gestures capture the perks of being a third-generation fixture in a small Western town.

Campbell’s father died in 1999 at age 86, and the son is looking to eventually retire as the last of a metal-bending breed. But he still goes down to Tonopah Station each day for coffee, jawboning and slapping his knee with a new generation of Emerson Titlows.

MAKING NEW MARK

And there’s a new generation of Campbell’s family making a hand-forged mark in Tonopah. His stepson, Adam Skiles, became fascinated with the metal shop and soon created a figure Campbell keeps on his property: A surf-and-sand character with dreadlocks and sneakers.

Skiles soon went on to create other figures now installed around town — statues representing area war veterans, a mining disaster hero and the brothers who helped found Tonopah.

Like his father before him, Campbell used a gentle hand to help carry on the metal-shaping trade in his family.

“I just gave him some once-overs and showed him how to weld,” he said of Skiles. “He took to it like a duck to water.”

Just like hammer-pounding John Campbell.