Las Vegas crews ready to raise Raiders stadium roof

There’s going to be a high-wire act at Allegiant Stadium this month and it has nothing to do with entertainment.

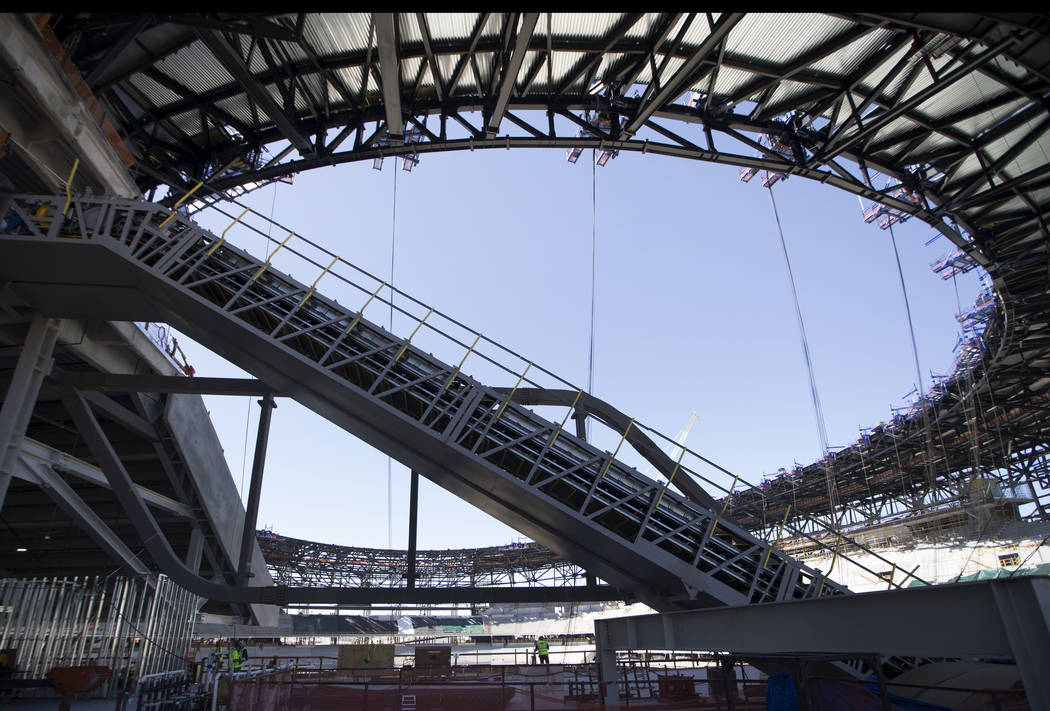

Construction crews under the direction of the Mortenson-McCarthy Joint Venture, general contractor for the 65,000-seat, $1.9 billion stadium that will become home to the Raiders and UNLV football next year, are preparing a highly choreographed work plan to begin construction of the translucent roof that will bring the games mostly played outside indoors.

Over the next six weeks, crews literally will be raising the roof.

A series of 100 stainless-steel cables have been laid out on the floor level of the stadium. They’re about 2½ to 3 inches in diameter with some as long as 800 feet.

“What they’re doing right now is laying those out,” said Don Webb, chief operating officer of the stadium construction subsidiary of the Raiders.

“If you look around the perimeter of the roof, you can see a number of gantry platforms where those cables will be pulled up into place, all 100 cables simultaneously, then attached to fixed points on the ring of the roof,” he said.

Cables to support translucent roof

The crosshatch pattern of cables will form a durable support system for a roof made of fluorine-based plastic known as ETFE — short for ethylene tetrafluoroethylene. Because the roof is clear, the stadium interior will be naturally lighted for day games in air-conditioned comfort.

From the field level, the cables when installed will be hardly noticeable, but they’re heavy-duty. Webb has an 18-inch sample of the cable in his office. It weighs 90 pounds.

That means the 800-foot cables — the ones that stretch the longest distance across the roofline, from end zone to end zone — would weigh about 24 tons each.

“Down here (at field level, where the cables are now laid out) those things seem enormous,” Webb said. “Once they’re actually up and in place, they won’t be invisible, but they will be less noticeable.

“They’re under enormous loads to provide the rigidity that a flexible cable could provide. The alternative would be a rigid, very large, very heavy truss system,” he said.

The cables arrived at the stadium site preassembled with fixed lengths. Because the cables must be taut, there’s virtually no give or stretching of them.

Choreographed hydraulics

The installation of the cable support net is being carefully choreographed through hydraulic units ringing the top of the stadium.

“Hydraulic lifts are pulling the cables up. They’ll pull them up a set distance — about 5 feet — then they reset and they repeat this many, many times over a space of six weeks,” Webb explained.

Eventually, the cables will be raised about 150 feet above the playing surface.

“Since it’s a hydraulic cylinder that’s operating, the throw of that cylinder determines how much cable is pulled at each lift. The process will be repeated many, many times and that’s why it will take a month and a half for this to be fully installed.”

Webb said the choreography of the project is impressive.

“It’s not just understanding all of the steps that have to be taken, but understanding the sequence that makes the most sense so you’re not painting yourself into a corner,” he said. “That’s why the schedule has 23,000 tasks on it and they simulate it (the roof installation) on the computer, animate it and run the simulation to see where everything is on any given day.”

The scheduling of the roof project is essential, but the final attachment of the cables to each node along the top level of the stadium will be subject to temperature fluctuations.

“The thermal expansion and contraction of this building will be several inches so there will be a prescribed range of temperatures for those final connections,” Webb said. “If it’s not within the tolerances, we will have to wait. That’s why we scheduled the way we did. We had to look ahead and anticipate when this is going to occur. We had to look at historic temperatures and figured out the time of day the final connections should be made.”

Enclosure scheduled next year

The installation of the ETFE roof won’t occur until early 2020, and that, too, will be a highly choreographed series of events.

“They’ll be lifting those panels from outside the stadium, which is why we’ll be using those enormous cranes,” Webb said. “It’s not that these ETFE panels are so heavy. They’re not. But they have to be lifted from outside the building and the boom of that crane has to extend across more than half the stadium width.”

Panels will be placed like puzzle pieces, but the choreography will be in leaving some of the roof open so that equipment within the stadium bowl can be lifted out by crane when it’s no longer needed.

While the roof won’t be in place until early next year and the building won’t be fully enclosed until March, there are still plenty of projects underway inside. In a stadium tour last week, the smell of fresh paint was wafting through the corridors as laborers worked in different levels and concourses. Some of the concession stands are also starting to take shape.

Webb said once the cables begin rising, workers can finish concrete pours on the floor and complete the field tray entry on what will be one of the most versatile stadium floor surfaces in the country.

The bottom level will be concrete and can support trucks, stages and live performance equipment. On top of that will be an artificial turf surface, the field of choice for the UNLV football team. On top of that will be the 4-feet-high movable field tray containing a heating and irrigation system and a grass surface that will be grown outdoors and moved inside for Raiders game days. The tray will take a one-eighth-mile, 90-minute journey on 13 rails every time it’s moved in and out of the stadium.

1,600 workers on site

There currently are about 1,600 laborers on the site in two daily shifts performing a wide variety of tasks while the roof-raising preparations are underway.

Webb said boilers, transformers and utility improvements have been installed and are being connected, and dozens of escalators and elevators are being installed and tested. Overall, work on the stadium is about 60 percent complete.

Another big milestone will be the installation of the first stadium seat, which likely will occur in January. About 80 percent of the seat decks are completed.

But Webb isn’t so excited about the first seat installation.

“It’s not so much the first seat that I care about, but the last seat.”

Contact Richard N. Velotta at rvelotta@reviewjournal.com or 702-477-3893. Follow @RickVelotta on Twitter.